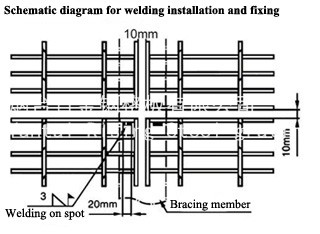

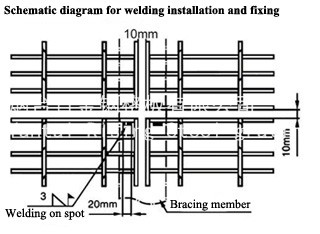

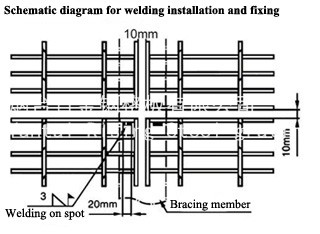

- Installation clearance of steel grating is 10mm and little adjustment is allowed. Each side of bearing bar's length in supporting beam where steel grating loads the two ends of flat steel is at least 25mm.

- Installation of steel gratings:Two methods can be used:welding and using saddle clips.Permanent steel gratings requiring no dismantling can adopt welding, to be welded onto its supporting beam;the concrete position is located in the first bearing bar of each corner for steel grating.Adopting saddle clips will have advantages of not damaging zinc coat and easy removing.The safest method is fixing by welding so that steel grating can't fall from beam due to loosening clips.

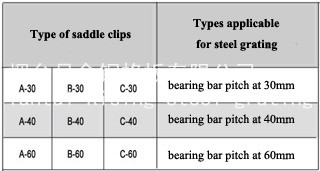

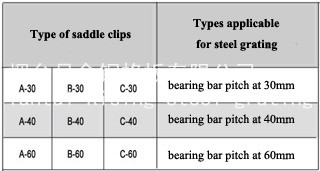

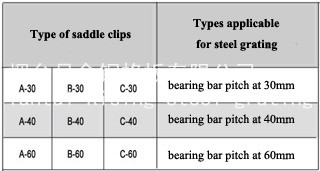

- Application of Saddle Clips:Saddle clip should be installed in the four corners of steel grating and must be fastened to the maximum extent to avoid falling off.At least 4 sets of saddle clips are required for each steel gratings and the quantity of applying saddle clips will increase as the length of a steel grating gains.

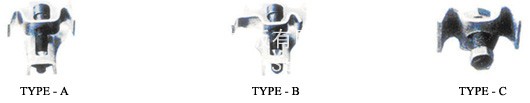

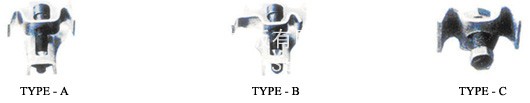

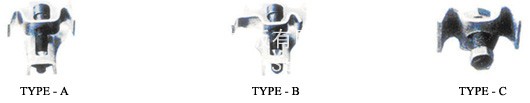

- Type A - composed of a top board with double hook,a holding down plate with teeth and an M10 (or M8) inner-hexagon-bolt.

- Type B - composed of a top board with double hook(where one hook can draw together two neighboring steel gratings),a holding down plate with teeth and a M10(or M8) inner-hexagon-bolt.

- Type C - composed of a top board with double hook and a M10 (or M8) hexagon-bolt which can be welded in the supporting structure.